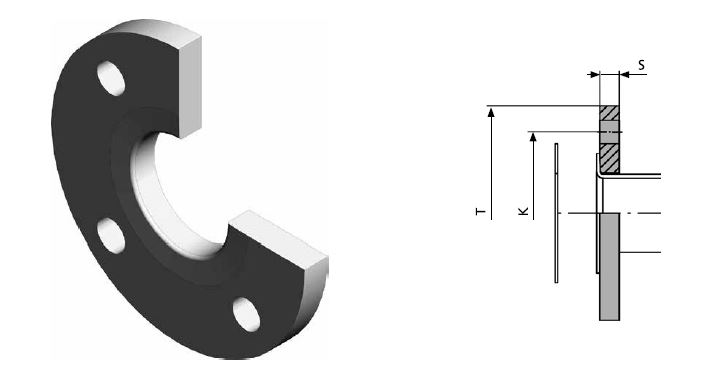

GS-90 Flared flange for DIN 2501

The 90° flange joint system is used for class II pipes with a maximum permitted working pressure of 20 bar. The 90° method is suitable for a system with low pressure pipes in a wide range of different materials ranging from carbon steel to super duplex.

Technical data

Drilled according to ISO 1092-1 (DIN 2501)

| Size | Pipe OD [mm] | Part no | Item No. Std | Item no HDG Surface | Item No. ZN surface | PN 10/40 | Bolts DIN 931 | Weight [kg] | Gasket Part No | Gasket Item No | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | K | S | ||||||||||

| 1 1/4″ | 38 | GSEN-PN10/40-DN32/38 | 1106103100 | 1116103100 | 1106303100 | 140 | 100 | 18 | 4xMl6x60(40) | 1.9 | DN32PN10-40 | 2701401000 |

| 42,4 | GSEN-PN10/40-DN32/42.4 | 1106103200 | 1116103200 | 1106303200 | 140 | 100 | 18 | 4xM16x60(40) | 1.8 | DN32PN10-40 | 2701401000 | |

| 1 1/2″ | 44,5 | GSEN-PN10/40-DN40/44.5 | 1106104000 | 1116104000 | 1106304000 | 150 | 110 | 18 | 4xMl6x60(40) | 2.1 | DN40PN10-40 | 2701402000 |

| 48,3 | GSEN-PN10/40-DN40/48.3 | 1106104100 | 1116104100 | 1106304100 | 150 | 110 | 18 | 4xM16x60(40) | 2.0 | DN40PN10-40 | 2701402000 | |

| 2″ | 57 | GSEN-PN10/40-DN50/57 | 1106105100 | 1116105100 | 1106305100 | 165 | 125 | 20 | 4xM16x70(45) | 2.6 | DN50PN10-40 | 2701403000 |

| 60,3 | GSEN-PN10/40-DN50/60.3 | 1106105200 | 1116105200 | 1106305200 | 165 | 125 | 20 | 4xM16x70(45) | 2.5 | DN50PN10-40 | 2701403000 | |

| 2 1/2″ | 73 | GSEN-PN10/16-DN65/73 | 1106106000 | 1116106000 | 1106306000 | 185 | 145 | 20 | 4xM16x70(45) | 3.0 | DN65PN10-40 | 2701404000 |

| 76,1 | GSEN-PN10/16-DN65/76.1 | 1106106100 | 1116106100 | 1106306100 | 185 | 145 | 20 | 4xM16x70(45) | 2.9 | DN65PN10-40 | 2701404000 | |

| 73 | GSEN-PN25/40-DN65/73 | 1106106200 | 1116106200 | 1106306200 | 185 | 145 | 22 | 8xM16x70(45) | 3.1 | DN65PN10-40 | 2701404000 | |

| 76,1 | GSEN-PN25/40-DN65/76.1 | 1106106300 | 1116106300 | 1106306300 | 185 | 145 | 22 | 8xM16x70(45) | 3.0 | DN65PN10-40 | 2701404000 | |

| 3″ | 88,9 | GSEN-PN10/16-DN80/88.9 | 1106107000 | 1116107000 | 1106307000 | 200 | 160 | 20 | 8xM16x70(45) | 3.4 | DN80PN10-40 | 2701405000 |

| 88,9 | GSEN-PN25/40-DN80/88.9 | 1106107100 | 1116107100 | 1106307100 | 200 | 160 | 24 | 8xM16x80(45) | 3.5 | DN80PN10-40 | 2701405000 | |

| 4″ | 108 | GSEN-PN10/16-DN100/108 | 1106108000 | 1116108000 | 1106308000 | 220 | 180 | 22 | 8xM16x70(45) | 4.7 | DN100PN10-16 | 2701406000 |

| 114,3 | GSEN-PN10/16-DN100/114.3 | 1106108100 | 1116108100 | 1106308100 | 220 | 180 | 22 | 8xM16x70(45) | 4.5 | DN100PN10-16 | 2701406000 | |

| 114,3 | GSEN-PN25/40-DN100/114.3 | 1106108200 | 1116108200 | 1106308200 | 235 | 190 | 26 | 8xM20x90(55) | 5.9 | DN100PN25-40 | 2701406200 | |

| 5″ | 133 | GSEN-PN10/16-DN125/133 | 1106109000 | 1116109000 | 1106309000 | 250 | 210 | 22 | 8xM16x80(45) | 5.8 | DN125PN10-16 | 2701407000 |

| 139,7 | GSEN-PN10/16-DN125/139.7 | 1106109100 | 1116109100 | 1106309100 | 250 | 210 | 22 | 8xM16x80(45) | 5.5 | DN125PN10-16 | 2701407000 | |

| 139,7 | GSEN-PN25/40-DN125/139.7 | 1106109200 | 1116109200 | 1106309200 | 270 | 220 | 28 | 8xM24x100(65) | 6.9 | DN125PN25-40 | 2701407500 | |

| 6″ | 159 | GSEN-PN10/16-DN150/159 | 1106110000 | 1116110000 | 1106310000 | 285 | 240 | 24 | 8XM20x80(55) | 7.5 | DN150PN10-16 | 2701408000 |

| 168,3 | GSEN-PN10/16-DN150/168.3 | 1106110100 | 1116110100 | 1106310100 | 285 | 240 | 24 | 8XM20x80(55) | 7.0 | DN150PN10-16 | 2701408000 | |

| 168,3 | GSEN-PN25-40-DN150/168.3 | 1106110200 | 1116110200 | 1106310200 | 300 | 250 | 30 | 8XM24x100(65) | 13.9 | DN150PN25-40 | 2701408200 | |

| 8″ | 219,1 | GSEN-PN1 0-DN200/219.1 | 1106111000 | 1116111000 | 1106311000 | 340 | 295 | 24 | 8XM20x90(60) | 9.5 | DN200PN10-16 | 2701409000 |

| 219,1 | GSEN-PN16-DN200/219.1 | 1106111100 | 1116111100 | 1106311100 | 340 | 295 | 26 | 12XM20x90(60) | 9.2 | DN200PN10-16 | 2701409000 | |

| 219,1 | GSEN-PN25-DN200/219.1 | 1106111200 | 1116111200 | 1106311200 | 360 | 310 | 32 | 12XM24x110(70) | 18.1 | DN200PN25 | 2701409200 | |

| 10″ | 273 | GSEN-PN1 0-DN250/273 | 1106112000 | 1116112000 | 1106312000 | 395 | 350 | 26 | 12XM20x90(60) | 11.1 | DN250PN10 | 2701410000 |

| 273 | GSEN-PN16-DN250/273 | 1106112100 | 1116112100 | 1106312100 | 405 | 355 | 29 | 12XM24x100(70) | 15.1 | DN250PN16 | 2701410100 | |

| 12″ | 323,9 | GSEN-PN1 0-DN300/323.9 | 1106112200 | 1116112200 | 1106312200 | 445 | 400 | 26 | 12XM20x90(60) | 12.7 | DN300PN10 | 2701411000 |

| 323,9 | GSEN-PN16-DN300/323.9 | 1106113000 | 1116113000 | 1106313000 | 460 | 410 | 32 | 12XM24x110(70) | 18.0 | DN300PN16 | 2701411200 | |

| 14″ | 355,6 | GSEN-PN1 0-DN350/355.6 | 1106113100 | 1116113100 | 1106313100 | 505 | 460 | 30 | 16XM20x100(65) | 26.0 | DN350PN10 | 2701412000 |

| 355,6 | GSEN-PN16-DN350/355.6 | 1106113200 | 1116113200 | 1106313200 | 520 | 470 | 35 | 16XM24x120(75) | 28.7 | DN350PN16 | 2701412200 | |

| 16″ | 406,4 | GSEN-PN1 0-DN400/406.4 | 1106114000 | 1116114000 | 1106314000 | 565 | 515 | 32 | 16XM24x110(70) | 35.2 | DN400PN10 | 2701413000 |

| 406,4 | GSEN-PN16-DN400/406.4 | 1106114100 | 1116114100 | 1106314100 | 580 | 525 | 38 | 16XM27x130(80) | 38.6 | DN400PN16 | 2701413200 | |

Material possibilities:

Part numbers for three different surface treatments (others on request):

– Standard – plain metal without coating

– HDG -hot dip galvanized (add HDG after Part no)

– ZN – electric galvanized (add ZN after Part No)

Component material: Carbon steel S235, other materials on request.

Manufacturing tolerance for flange thickness ± 5%

L= flange to flange

(L)= flange to block

Gasket material:

Standard= Klingersil® C-4430

Other materials on request.

Part numbers for three different surface treatments (others on request):

– Standard – plain metal without coating

– HDG -hot dip galvanized (add HDG after Part no)

– ZN – electric galvanized (add ZN after Part No)

Component material: Carbon steel S235, other materials on request.

Manufacturing tolerance for flange thickness ± 5%

L= flange to flange

(L)= flange to block

Gasket material:

Standard= Klingersil® C-4430

Other materials on request.

Category: 10-40 BARS